The rapid growth of cross-border e-commerce has transformed global trade, with millions of products—from small household items to consumer electronics—shipped by air every day. However, many of these goods contain magnetic materials that can interfere with aircraft navigation systems, posing Class 9 Dangerous Goods (DG) risks, delaying shipments, and increasing safety concerns.

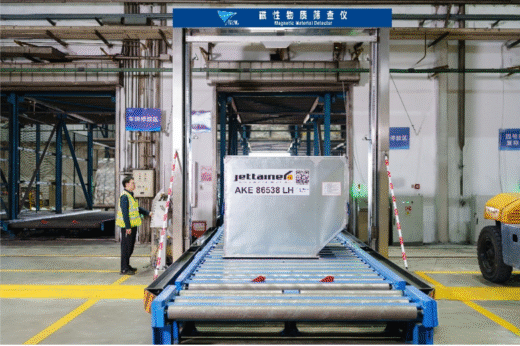

To address this challenge, Shanghai Pudong International Airport Cargo Terminal Co., Ltd. (PACTL) has introduced a patent-pending Magnetized Material Detector capable of conducting rapid, full-pallet screening.

Tackling a Growing Safety Challenge

“Traditional inspections rely on labour-intensive, piece-by-piece checks and extensive reporting,” explained Lu Min, Deputy General Manager of PACTL and leader of the Magnetized Material Screening Project.

“A single ULD can contain thousands of mixed items, making it increasingly difficult to ensure safety and compliance efficiently.”

The new Magnetized Material Detector, developed in collaboration with the China Academy of Civil Aviation Science and Technology, addresses these concerns by combining advanced sensors with intelligent algorithms.

How the Technology Works

- Equipped with four TMR sensor arrays in a gate-style frame, the system provides all-directional magnetic field analysis at the pallet or ULD level.

- Multi-dimensional algorithms allow for precise risk identification and localization, distinguishing harmless magnetic components from hazardous materials.

- A three-tier scanning system (quick, semi, and full scan) adapts to different operational requirements.

This innovation ensures compliance with IATA DGR (Dangerous Goods Regulations) while reducing labour hours, inspection costs, and safety risks.

Benefits for Airlines and Forwarders

The system allows airlines, freight forwarders, and cargo terminal operators to conduct fast, accurate, full-pallet compliance checks without disrupting cargo flows. By preventing shipment rejections and delays, it supports both aviation safety and global e-commerce supply chain reliability.

Looking Ahead

PACTL is working to further enhance the system with:

- Data integration and storage capabilities for improved traceability.

- Modular and lightweight designs for easier deployment and upgrades.

- Adaptability to diverse operating environments, ensuring global applicability.

Carsten Hernig, Deputy General Manager, Sales & Marketing and Production at PACTL, said:

“Magnetic hazards have long been a challenge for the air cargo industry. This detector enables us to identify those risks at the pallet level, improving detection accuracy and reducing manual workload. Most importantly, it strengthens aviation safety—which is what our airline customers value most.”