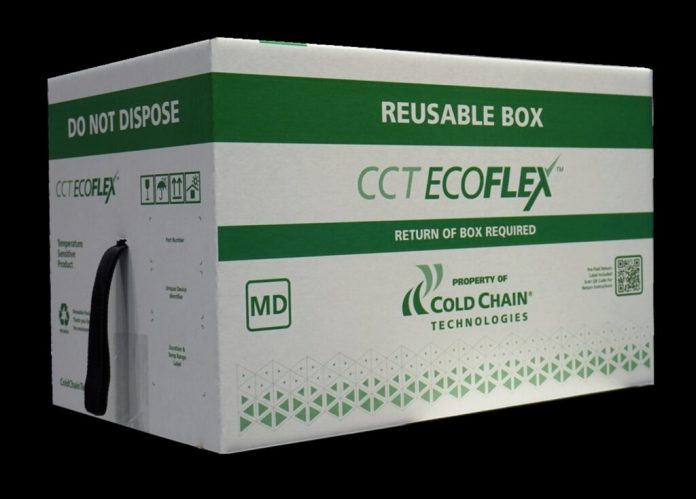

Cold Chain Technologies (CCT) has expanded its portfolio of reusable temperature-controlled packaging with the launch of the EcoFlex 3, the latest evolution of its shape-stable, full-coverage PCM shipper family designed for high-performance cold chain logistics.

The new generation introduces a series of technical enhancements developed in direct response to customer feedback, strengthening the system’s performance, usability, and sustainability credentials.

Enhanced Performance for Dry Ice and PCM Shipments

A key upgrade in the EcoFlex 3 is the integration of CCT’s AirShield technology for dry ice shipments. The system strategically manages gas flow to prevent supercooling events while slowing sublimation, extending the duration and reliability of dry ice–based temperature control.

The shipper also features a redesigned lid mechanism. Unlike previous generations, the EcoFlex 3 lid connects directly to the shipper’s core rather than the uppermost vacuum-insulated panel (VIP). This provides improved durability and allows users to safely add dry ice without disturbing the payload—a significant advantage for regulated or sensitive products requiring minimal handling.

Streamlined Reuse, Reduced Waste

EcoFlex 3 introduces upgraded core-wrapping technology, enabling faster refurbishment and reducing material scrap. The system is designed for reconditioning only once during its life cycle, shortening redeployment timelines and supporting CCT’s large-scale reusable network.

Each shipper arrives fully conditioned with pre-printed return labels for seamless dispatch to CCT’s reconditioning facilities. After refurbishment, units are redeployed through CCT ReNew, the company’s digital tracking and assurance programme, offering visibility into asset performance and life cycle metrics.

To further support customer ESG commitments, CCT’s reusable dashboard includes a “Track Your Landfill Avoidance” tool, providing quantifiable reporting on avoided waste.

To date, more than five million EcoFlex shippers have been deployed, collectively preventing 55 million lbs of material from entering landfill—making it the largest reusable fleet in the market.

Sustainability and Cost Efficiency at the Core

EcoFlex reusable shippers offer up to 60.3% fossil fuel reduction compared with standard single-use alternatives. The EcoFlex 3 also includes refreshed artwork to reinforce its reuse-first design.

David Webber, Senior Global Marketing Manager at Cold Chain Technologies, said:

“EcoFlex 3 represents a new level of reusable capability for temperature-controlled shipping, offering a robust thermal packaging solution that minimises payload interference, simplifies packing and unpacking, and enhances our reusable programme.

The purpose of the range is to provide customers with solutions that minimise waste and CO₂ emissions, optimise packaging and freight processes, and manage thermal, mechanical and regulatory risk. EcoFlex 3 delivers all of this alongside cost and space-saving efficiencies, making it ideal for highly regulated industries aiming to meet sustainability goals without compromising on quality.”

EcoFlex 3 is available in four sizes and four temperature ranges, with additional formats planned for release in 2026.

Share

Read more